Fully machined

One big milestone achieved by January 2024 was that all parts were machined! That’s 42,000 pocket parts in total just for the Pocket Drivers that have each been machined and finished. It has took a bit longer than we expected but we did allow for additional time which didn’t cause any delays.

This was a huge moment for the campaign as with those parts complete, every part of Pocket Driver, every add on, and every screw, was then on the move to us in some way or another if we didn’t already have it.

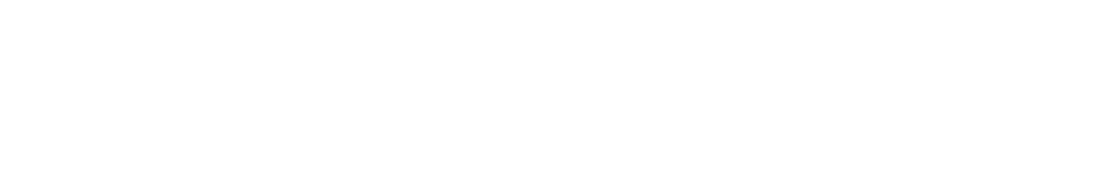

A half machined magnetic bit case in its final stages.

From silver to gold

We had the polished stainless steel sets successfully gold plated and they looked great! The platers did unfortunately also plate the bearing surfaces between the chuck and the main body. We think this happened this time because they were dip plated rather than brush plated so the gold got everywhere.

With a 2 micron layer applied that added up to a total of 8 microns of error, we got them set them up in the lathe carefully with a collet, wrapping them to protect the gold, used a file and sandpaper to remove the gold on those surfaces. At least there were only 20 of these, and the soft gold gave the machine a fun golden shimmer. It could be the most expensive dust around!

Assembling

Deliveries

The moulded pulp arrived 'mostly' intact after is long voyage, though at some point a forklift fork had been driven through the side of the boxes so 500 were damaged. Those were remade and airmailed... on the bright side the other 7500 were ok so we had more than enough to get started!

We were able to crack out our new (borrowed) toy "Liftamus prime" as it was lovingly named by Ryan and the production team. Basically, it's a manual fork lift! Since we don't have enough space for an automated forklift this allows us some lifting freedom in a much smaller space. Here it is in motion moving some metal around.

Share:

A seamless look into Wire Electrical Discharge Machining (Wire EDM)

Getting to Grips With the Fractal Vise