Pre-Production Run

Back in July 2023 we’d just received the Pocket Driver pre-production run and were super happy to report that we... almost nailed it first time! There were some very small details that needed tightening up and a few additions we had made.

Ball Plunger Clearance

This one was us trying to be clever and it backfired a little bit. We specified the tolerances between the plunger ball and handle perfectly and didn't take into account the real world and tolerance build up. On a couple of the samples the clearance just didn't exist, so the handle put a huge sideways load on the ball, which did depress the ball but also damaged the housing meaning the ball was stuck in it's depressed state. Poor ball.

This was resolved nice and quickly, by simply adding in the clearance that was needed to begin with and also building in other small mods to make sure this couldn’t happen in the production models.

Barrel Pin Strengthening

We had been putting the Pocket Drivers through their paces by putting them under excessive loads, generally pushing them to breaking point to root out any weaknesses in this batch and we noticed a potential fail point on the barrel pin. The cross sectional wall thickness where the M3 brass pin handle screws into it was too small for comfort, so reduced that to M2 to beef it up a little. This didn’t affect its use in any way to you guys, it just helped us sleep at night!

Spring Power Reduction

This one is a big one for us. We finally achieved the feather light action we were all dreaming of! Because Pocket Driver is designed for light tasks like working on tiny electronic assemblies, we really wanted to remove as much resistance in the mechanism as possible, so we did a number of things to achieve this:

- Improved the surface finish on the end of the barrel pin to reduce surface friction

- Adjusted the glide angle (the angle that the two surfaces meet)

- Changed the spring diameter (which reduces the load the spring can apply)

All of these very small changes resulted in a silky smooth ratchet that helps prevent back driving your screws on the return ratchet stroke.

Custom Shoulder Screw Had the Wrong Finish

This was a little frustrating, but not the end of the world. Our supplier supplied nice and shiny screws for the first sample run and then on the larger pre-production run, thought they'd miss a step and send us dull grey looking things. Simple fix on this one, do em again!

Packaging

We stepped up our packaging game this time round and had custom moulded inserts made to help protect your Pocket Drivers as they travel the world. They're made from waste paper, so can easily be recycled or kept as a nice home for your Driver.

Barrel Extender Mod

The barrel extender was designed during the campaign in tandem with you guys, and we were all huge fans of it here at MetMo. However, it was pointed out over on CubeClub almost straight away, that when you install your barrel extender, what do you do with your end cap?? Oops…

With that in mind we modified it straight away, so you can simply screw your end cap into the end of the barrel extender and it will look exactly like the original design without the potential to lose your end cap whilst on a job.

There is also a small void there for you to store secrets in.

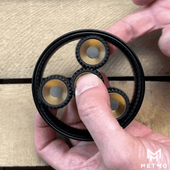

Laser engraving

We have wanted to mark our products for a long time, but could never quite get it right... Until now! (Or so we thought). We branded the magnetic bit case up with our MetMo logo to try out laser engraving on aluminium and we were super happy with how it turned out. From then we started playing around with how to engrave stainless steel.

We went with a simple marking that pays homage to the original Weltrekord Driver, showing our name, patent number and year of design. Marking our products will also help with the development of MetMo as a company and as a trusted brand.

The Copycats Are At It

Unfortunately with the success of our recent campaigns, the copycats were moving in and running scams using our brand or producing very poor copies of our designs. Having the MetMo Mark going forward will help to ensure you have the real deal!

We only sell on our store, KS and IGG at the moment, so do send us a message if you spot a MetMo out in the wild that doesn't look quite right.

Thank you to everyone that has already helped spot the copies and scams so far, it's a huge help and aids with them being taken down as fast as possible. We are also now set up with legal support that is actively helping us combat this problem.

If you want to help us out even more - If you get served an ad for one of our products that isn't from MetMo, please send us the url link of the ad directly. This isn't something we can access from the websites of the copycats, as they like to keep their ad accounts separate for shady reasons.

MetMo Driver - Reloaded

We had some amazing feedback throughout both the Pocket and original Driver campaign about what the product lines should include. From that we went away and had a hard look at what you guys actually want and have developed our new Driver lineup that aligns with our Pocket Driver offering.

MetMo Driver Black - MetMo Driver Black Steel - MetMo Driver Stainless Steel

MetMo Driver - Black

Our classic and most popular Driver with a machined aluminium body. Built like a tank, as standard.

MetMo Driver - Black Steel

Black steel is the perfect balance between robust stainless steel and lightweight aluminium, putting all of the weight at the business end of the Driver. We've also included an upgraded handle which has internal storage for 5 x 50mm bits.

MetMo Driver - Stainless Steel

The stainless steel model is an absolute beast of a Driver, weighing in at over 600g, it's a tool that will survive anything you throw at it. This premium Driver also has the upgraded bit storage, but produced from solid stainless steel.

Share:

Pocket Driver: Origins, Development & Production

Tat or treasure: Understanding the value behind antique tools (with examples)