A lot of things move. And every machine that moves – from drills to cars to bikes to robots – owes its muscle and manners to a gears… and torque.

Torque is what lets a car pull away from standstill (without the engine exploding), a winch lift a load that weighs more than your grandad’s old lathe, or a drill bite into wood without stalling mid-screw.

And every turn of a gear tooth, every change in diameter angle alters how that torque behaves. This usually happens inside some form of housing – aptly, a gearbox.

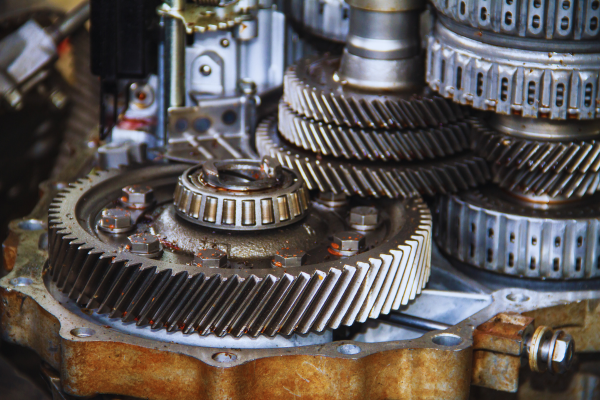

So let’s crack open that box (literally and conceptually) and explore how gearboxes work, how they shape torque output and why even the smallest design decisions can transform how machines feel, sound and perform.

Let’s go.

What actually happens inside a gearbox?

I’ll keep the philosophical stuff brief. But, in ways, a gearbox is like a metaphor for life: a bridge between power and purpose. Where, more often than not, shift happens.

*Tumbleweed…*

Let’s get them out the way early doors. Onwards…

Most motors are built for speed, not strength. In other words, they spin fast but generate small amounts of rotational force. A gearbox (gradually) flips this on its head.

By connecting the motor to a series of interlocking gears (a gear train), we can covert fast, light motion into slower, stronger motion. As a wise man once said, energy is not created nor destroyed but transformed from one form to another. So, when a small gear drives a larger gear, the larger gear rotates slower but produces more force. A force named torque.

Side note: Gears (and thus gearboxes) are used for other reasons too. For example, reversing the direction of rotation, moving rotational motion to a different axis or to keep rotation of two axes synchronised. Different gears do this better than others – and we’ll look at them later. But for most of this article, we’ll think of gears/gearboxes in terms of speed/force.

Now, the beauty of gearbox design lies in balance – like a battle of trade-offs – between speed and strength, efficiency and endurance, and precision and power. It’s generally the application that determines what wins.

Inside, you’ll find a few key components:

- Gears. Duh. Spur gears for simplicity. Helical for smoothness. Bevel for right-angle drivers. Worm gears for massive torque in tight spaces.

- Input shaft. Brings energy in from the motor.

- Output shaft. Delivers the transformed motion to whatever needs moving.

- Housing. Keeps everything protected from rogue bits of nonsense, reduces noise, and helps dissipate heat.

Ratios might sound scary, but they’re not too bad really. Every gearbox has one. The gear ratio is the number that tells you how many times the input gear must turn to make the output gear rotate once. In its simplest form:

This tells us how much the speed is reduced, and how much the torque is multiplied. A larger driven gear (more teeth) means higher ratio, lower speed, higher torque.

Since the following is true:

You can also express Gear Ratio (GR) in terms of rotational speed:

So a 6:1 ratio means the motor spins six times while the output turns once. The output moves six times slower but delivers six times more torque. Simple maths, eh. Not so scary after all.

Complex gearboxes often stack multiple stages to achieve even greater ratios. Each stage compounds the previous one, letting engineers multiply torque in surprisingly small spaces. It’s like mechanical Lego, and when done right, it's beautiful. But for some bigger applications, with big scary engine speeds, a mild headache.

To find your overall gear ratio, multiply gear ratios of each stage:

Simples.

Torque explained

Torque is rotational force – the measure of how strongly something twists. You feel it every time you turn a doorknob, pedal uphill, or try to open a jar that’s been welded shut with dried pasta sauce.

In engineering terms, torque is force multiplied by distance from the centre of rotation, measured in Newton-metres (Nm). So, in the world of gearbox design, torque is everything. It’s what actually moves the load.

But to get it right, like we saw earlier, is a balancing act. The gearbox needs to be cost-effective, efficient and still produce enough torque to move the load without exceeding its rated limit (i.e., it’s max performance level). Otherwise, gears chip, bearings wear, and service life plummets faster than my monday motivation. That’s why engineers build in safety factors, accounting for shocks, sudden starts, and the general chaos of the real world.

Torque and speed are two sides of the same coin. When one increases, the other decreases. Power stays roughly constant, but, like our wise man told us, its form changes.

A high gear ratio slows everything down and multiplies the torque – perfect for lifting heavy loads or moving with surgical precision. A low ratio keeps things fast and light, ideal for fans, propellers or anything that needs to spin like it’s had a few too many sweets and cups of coffee.

But outside of textbooks, every gain comes with a cost. Friction sneaks in with every gear that meshes and steals a little energy. Well-designed gearboxes generally achieve efficiencies between 70-98%, depending on the gear type.

For example, parallel-axis gears (spur, helical) hit the high end because they rely on rolling contact. Worm gears can drop to 30% efficiency because of sliding friction, but they’re compact and self-locking – and sometimes that trade-off is worth it.

Who or what was the first to turn? (A brief history of gearboxes)

Believe it or not, the gear isn’t a human invention – not entirely, anyway. A tiny insect called Issus Coleopterous (a bit like a jumping fly-come-shield bug) evolved with what looks like “gear teeth” on its leg to synchronise its jumps.

That’s not to say it inspired gears as we know them, but they did exist before.

Anyway, for humans, gears appeared in ancient China around 800BC, and the Greeks weren't far behind. The Antikythera Mechanism, built around 100BC, was essentially a bronze “computer” of interlocking gears that predicted celestial events.

Fast-forward to the Industrial Revolution, and gears became essential. Early cars used belt drives – strips of leather shifting between pulleys. Then in 1894, René Panhard and Émile Levassor created the first recognisable gearbox: a three-speed, chain-driven design. Louis Renault improved it by swapping the chain for a driveshaft, and the modern drivetrain was born.

Early gearboxes were unsynchronised “crash boxes”, where you had to match engine speed by ear. Then in 1919, synchromesh arrived, letting gear speeds match automatically. No grinding, no drama (well, less drama). Cadillac brought it to market in 1928, and drivers everywhere breathed a sigh of relief. As did their ears.

Today’s gearboxes are nothing short of engineering masterpieces. Commonplace, yes, but still very impressive. After standing on the shoulders of so many greats, tolerances are now measured in microns, materials are heat-treated to withstand decades of punishment, dual clutch systems can shift faster than you can blink, and in electric vehicles, single-speed transmissions are proving that sometimes less really is more.

Okay, so they’ve come a long way. Lots exist. But not all gears are created equal. Some prioritise strength, others silence, some compactness, others cost. Here’s the lineup:

Straight teeth, simple design, efficient but noisy. They’re the workhorses of low-speed applications.

Angled teeth for smoother, quieter operation. They can carry more load than spur gears because multiple teeth engage at once, spreading the force. The trade-off comes with axial thrust.

Double helical (Herringbone) gears

Two helical gears are mirrored and joined. They look like the Citroën logo (thanks to the same inventor). And they cancel out thrust forces. But don’t be fooled, these are still real powerful. They’re also quiet and expensive. So they’re used where performance matters more than budget.

The conical shape allows motion to turn corners, literally. Perfect for differentials and compact right-angle drives.

This is a screw driving a wheel. Massive torque reduction in one stage, self-locking ability, but terrible efficiency. Great for lifts and conveyors where you need things to stay put.

No, not the gland in your throat. Offset bevel gears with larger contact areas. They’re why modern cars accelerate smoothly without sounding like angry dentist drills. Brrrr.

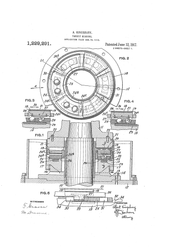

A central sun gear drives multiple planet gears orbiting inside a ring gear. Compact, strong, efficient and rather beautiful to look at. The darling of power tools, EVs and robotics. If gears had a favourite child, this would be it.

Like this one for Helico, but bigger.

How a gearbox multiplies torque

At its heart, torque multiplication is just leverage wrapped in circles. When a small gear drives a larger one, the larger gear moves more slowly but with far greater force. Every tooth acts like a tiny lever arm, and the geometry determines how efficiently energy transfers.

A 10:1 gearbox means the motor spins ten times for every single output rotation. Speed drops by a factor of 10 and torque increases tenfold. Again, the gearbox isn’t creating energy, it’s repackaging it in a form that's more usable.

The relationship is generally nice and simple… but of course, more complex versions exist.

That efficiency term, as we saw earlier, is usually between 0.7 and 0.98 too.

Could we chase infinite torque?

If a higher gear ratio produces more torque, what happens if you keep increasing it? Could you build a gearbox that delivers infinite torque?

Mathematically, yes. If you had an infinitely small driving gear turning an infinitely large driven gear, the ratio would approach infinity. Multiply any finite torque by infinity and you’d get infinite output force. Problem solved, physics defeated, let’s all go home.

Errr… *reality enters the chat*

First, no material is infinitely strong. Every gearbox has a rated torque limit before teeth sheer, bearings seize, or housings crack. Steel, bronze, titanium – they all have boundaries. Even advanced composites will eventually say “no thanks” and fail.

Second, efficiency eats away at you. Friction between gear teeth, lubrication drag, and heat generation mean no gearbox reaches 100% efficiency. Worm gears can lose up to 70% of input power to friction. Stack enough reduction stages, and you’d waste more energy than you deliver.

Third, speed vanishes. At an infinitely high ratio, the output shaft would move so slowly you’d need geological timescales to see it turn. Infinite torque, yes – but zero useful work. Power, after all, is torque times rotational speed. One goes to infinity, the other to zero, and you’ve achieved something beautifully pointless.

Finally, space and safety impose limits. Real machines must fit within housings, meet weight constraints, and survive shocks and sudden stops. Engineers design with safety factors to ensure reliability – not theoretical perfection.

The pursuit of infinite torque isn't about building an impossible gearbox. It’s more understanding why perfection doesn’t exist – and why the art lies in balancing the right conditions, not the most extreme.

Gearbox materials, gearbox geometry and gearbox motion

Now, you’re familiar with torque, let’s look at some torque-y side quests beyond the ratios. In particular, how force travels through matter and whether that matter can handle the stress.

Modern gears use alloy steels, often case-hardened through carburising or nitriding. This creates a hard, wear-resistant surface wrapped around a tough, flexible core.

Tooth geometry matters enormously. Helical gears outperform spur gears in torque capacity because multiple teeth share the load simultaneously. The involute profile – standard in most gears – maintains constant speed ratios and smooth torque delivery. Even small tweaks, like raising the pressure angle from 14.5º to 20º, measurably increase tooth strength and load capacity.

Alignment is equally critical. Misaligned gears waste energy correcting themselves, introduce vibration and wear prematurely. I’m going to get a bit philosophical again and say that every gearbox/machine has a voice – a hum, whine, growl (or if you’re rather unlucky, a bark). This is energy changing form. When a gearbox takes on a heavy load, that sound deepens. More torque means more friction, higher pressure and more energy escaping as heat and vibration.

Let’s torque up and summarise. A gearbox isn’t just some intricately shaped lump of metal. It has power (in one end). And purpose (out the other). Every ratio, every gear tooth, every material choice affects the connection and the amount of torque that comes out.

We looked at how gearboxes, like almost everything, are a trade-off between variables – more torque, less speed; more compactness, less efficiency; more power density, more heat to manage. Yada yada.

Oh, and that your gearbox has a voice. Just not one you can talk to (yet).

But if you do want to talk about it, come join us in the MetMo subreddit or CubeClub Forum. We’d love to hear what you’re building, breaking or just geeking out over.

The finally, if you want to experience some torque yourself, here are some MetMo creations to try:

A high torque, ratcheting hand driver built for REAL work. Up to 70Nm of it.

MetMo Pocket Driver

Like the former, but smaller. It keeps the same smooth gearing and control, just in a lighter version that fits snuggly inside your pocket.

Learn more about the Pocket Driver.

MetMo Helico

Quite possibly the ultimate desk toy. See a mini Spur or Herringbone gear in action – and feel your stress roll away.

Share:

How to Grow Your Fractal

A Gripping Story