The MetMo Blog

We love all things engineering. From deep dives into our products to historical explorations, there’s a wealth of information just waiting for you on the MetMo blog!

Pro tip! Search ‘Driver History’ to really get your teeth in.

Latest Blog Posts

The Ti-tan material that never Ti-res

Discover why titanium is one of the most impressive engineering metals in use today. This in-depth guide explores titanium’s properties, history, and real-world applications, explaining its exceptional strength-to-weight ratio, corrosion resistance, heat tolerance, and biocompatibility. Learn how titanium compares to steel, stainless steel, and aluminium, why it’s challenging to machine, and why it’s chosen for aerospace, medical, marine, and precision tools. A must-read overview of what makes titanium worth the cost—and the effort.

Meet the add-on that turns your Fractal Vise into a teleporting workbench wizard. Snap it off one setup, drop it onto another, or run it free-standing in seconds—no faff, no fuss. It adds height and locks down solid. Bonus: it even moonlights as a tiny vise when you’re in a pinch. Portable, bombproof, and dangerously convenient—proper maker magic.

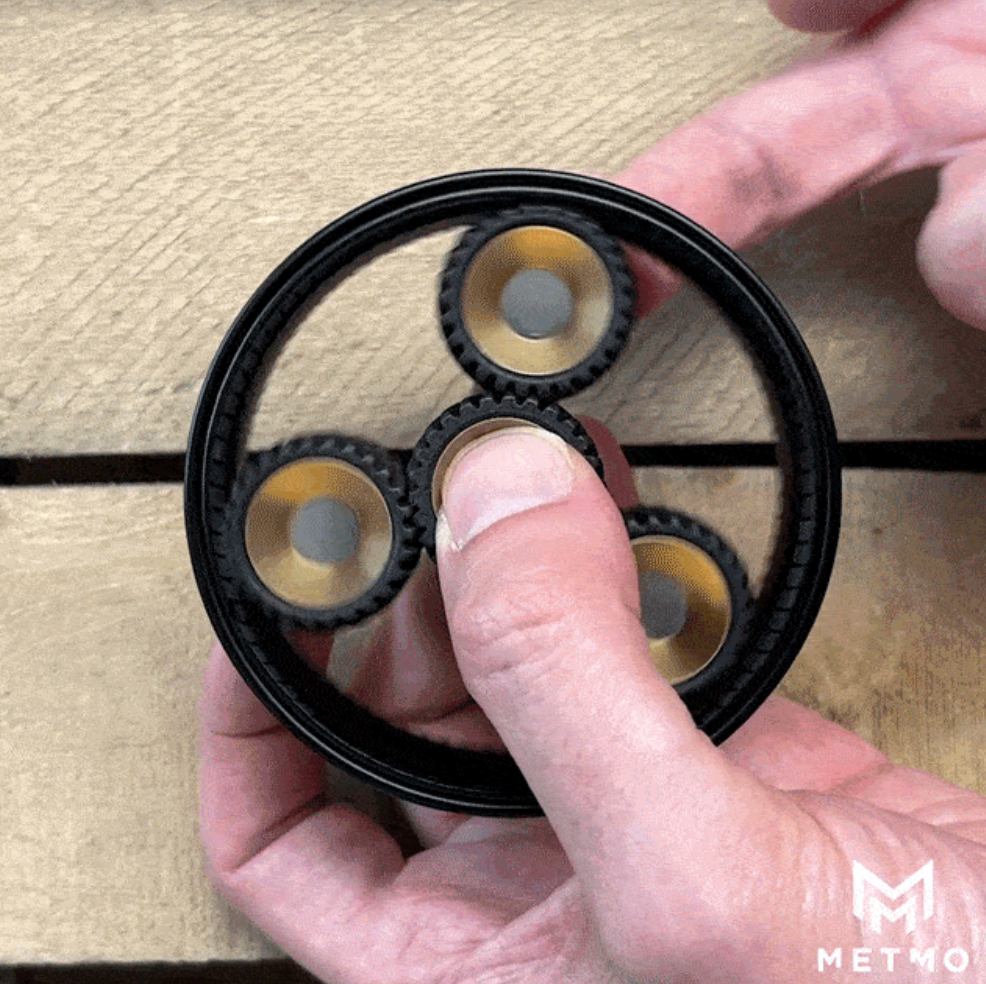

Planetary gears explained: A design written in the stars

Planetary gears are the David Beckham of the mechanical world—effortlessly smooth, unfairly capable, and adored by just about everyone. This star-struck guide takes you through how these cosmic little gear sets work: a sun in the centre, planets orbiting in perfect harmony, all wrapped inside a ring and carried along for the ride. Swap which part spins, stops or outputs and you unlock everything from torque-boosting reductions to high-speed overdrive. They’re compact, efficient, low-backlash and happy to share the load—no divas here—but they do demand tight tolerances, smart materials and proper care. From drills to drones to Mars rovers, planetary gears have earned their stellar reputation. And if you fancy making your own, just keep your planets aligned… and please show us when you do.

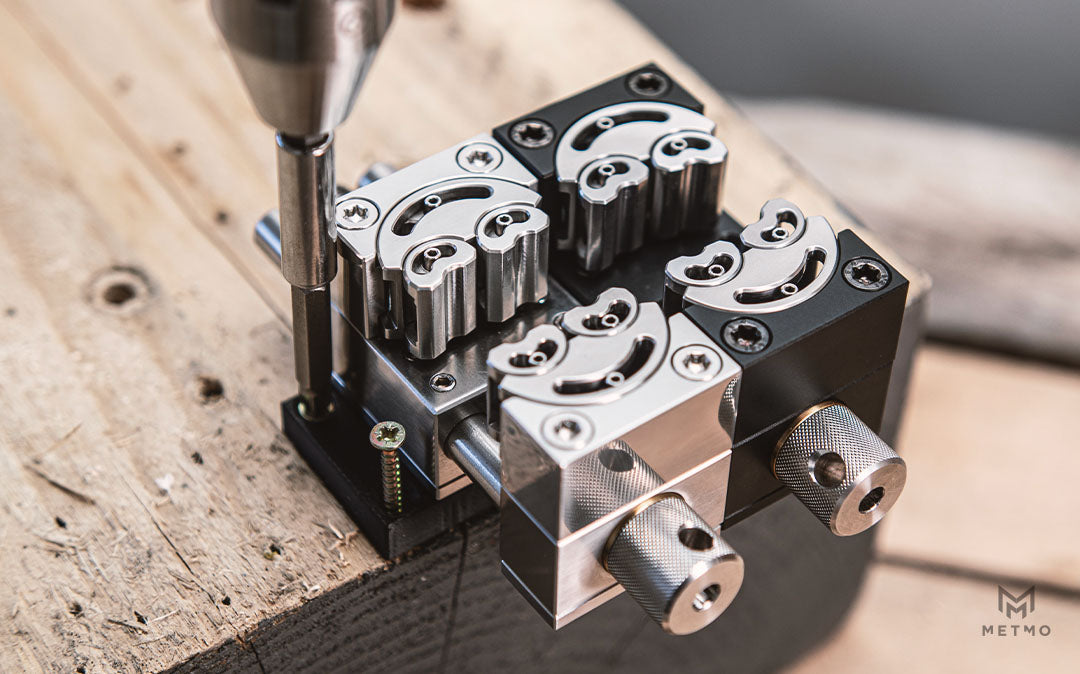

This blog takes you behind the scenes of the MetMo Fractal Vise — from its early experimental clamp concepts to the final precision-engineered design. It explores the evolution of fractal mechanisms, the challenges of achieving perfect clamping geometry, and the rigorous FE analysis and load testing used to push the vise to its limits. Along the way, the team shares design insights, testing results, and a few laughs from the development journey that turned an idea into an indestructible engineering masterpiece.

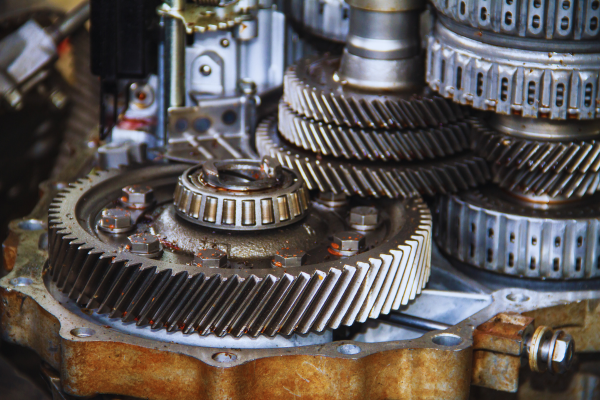

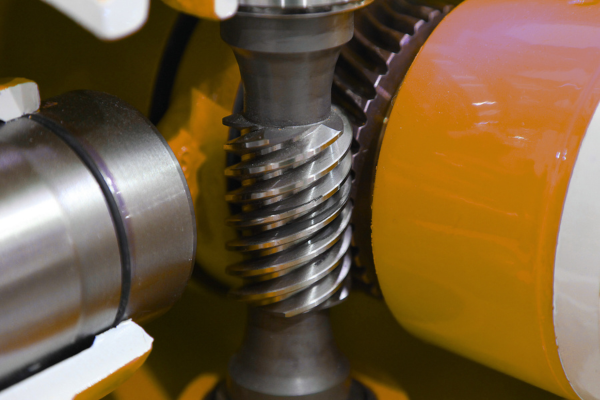

Time to torque about gearboxes

Torque. Gears. Gearboxes.

They turn fast spin into real muscle. Every machine — from drills to EVs — relies on this trio to trade speed for strength.

Gearboxes are all about balance: power in, purpose out. Spur, helical, bevel, worm, planetary — each with its own strengths, sounds and quirks.

Chase infinite torque and physics pushes back. The real magic is in the trade-offs.

And if you want to feel that torque yourself? Meet the MetMo Driver, Pocket Driver and Helico.

This blog explores new Fractal Vise add-ons, including the Dual Vise Adaptor Plate for expanded clamping and mounting options, and the 32mm to 82mm Conversion Kit for easy size upgrades.

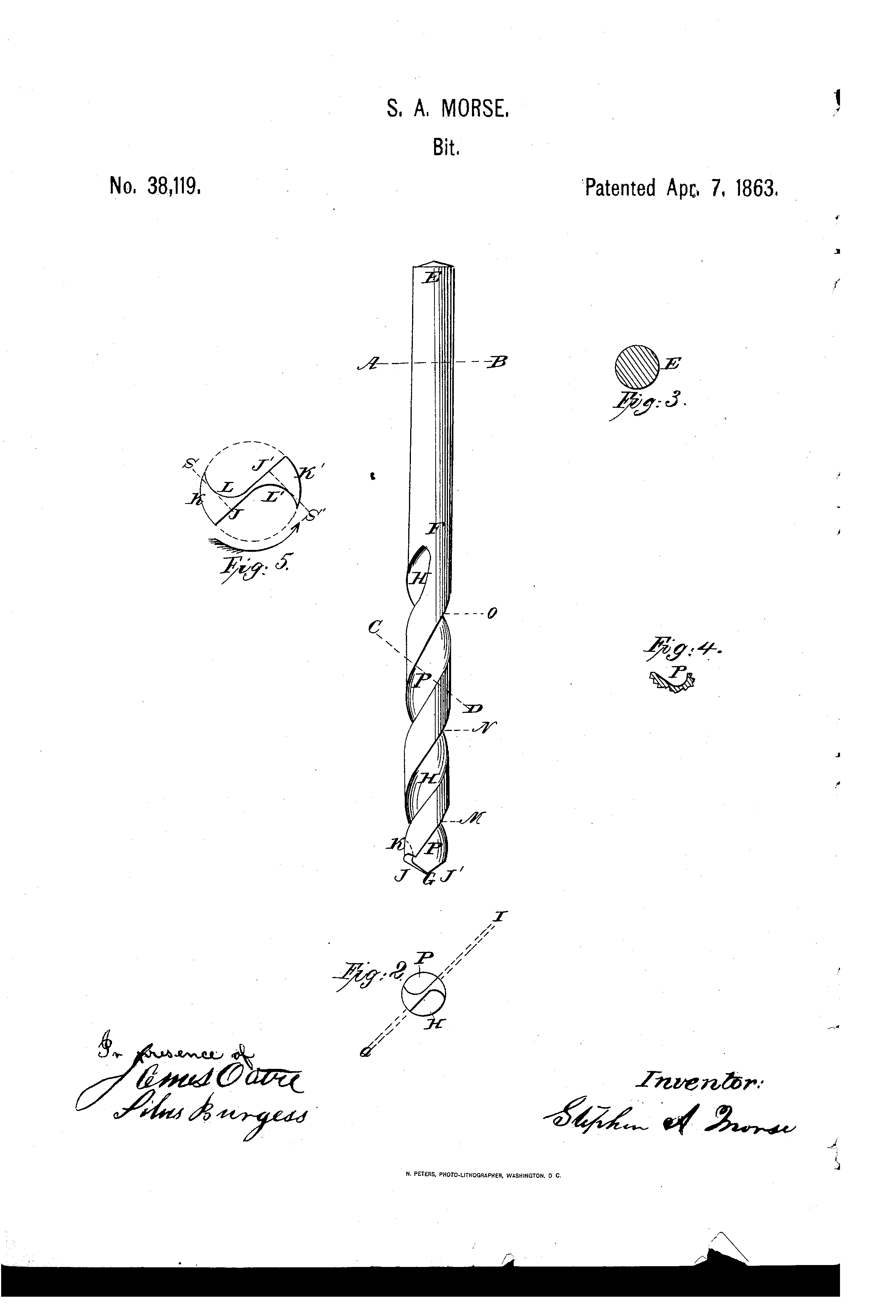

The hole history of manual drills

From spinning sticks to space-age drills, we take a whistle-stop tour through 35,000 years of drilling history.

Awls, bow drills, Roman augers, breast drills, and the twist bit that changed everything—each invention built on the last in humanity’s never-ending quest to make holes faster, cleaner, and with more satisfying torque.

Power tools may have taken over, but manual drills still hold a special place in our hands (and hearts). Quiet, precise, and endlessly tactile—just the way we like them at MetMo.

If you love putting holes in wood the old-school way, you’ll want to give this one a spin.

Take A Look At Our Little Bits

The Fractal Vise is made up of 17 unique parts and 46 components, each designed with precision and purpose. From the Medium Fractal at the core to the hardened Small Fractals and symmetrical Upper Fixed Jaws, every element plays a role in delivering smooth, reliable clamping. The Stub Shaft controls movement, aided by a brass ring for silky turns, while the Posts of Power and guiding dowels keep everything aligned and running true. Even the silicone base and cross bar are carefully considered for grip and adjustability.

Behind the scenes, a mix of hardened steels, over-engineered fasteners, and thoughtful upgrades ensure strength, durability, and a satisfyingly refined experience. It’s compact, clever, and overbuilt in all the right ways—because why settle for less?

The one-way wriggle around worm gears