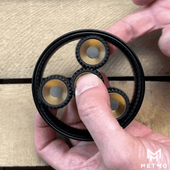

We're stripping down the Fractal Vise and taking a detailed look at the design details of each component, in probably way too much detail (who’s to say...)

The Fractal Vise is made up of 17 unique parts and 46 components in total, so let's first look at how all these parts connect!

How To Assemble A Fractal

We've managed to get this video down to 3:30, but in total it takes around 10 minutes to methodically assemble a Fractal Vise, and boy are those some satisfying minutes (volume up for maximum joy!).

But why are all these parts designed the way they are? Well, hang on to your hats people, the details are here! Let's kick it off with everyone’s favourite happy frog.

T̶h̶e̶ H̶a̶p̶p̶y̶ F̶r̶o̶g̶ The Medium Fractal

The one that sits between them all (or Leonardo as he's commonly known) cradling the small fractals and interfacing with the outer jaw. This is the second stage of the fractal mechanism and one of the most difficult pieces to machine, making this one of the most expensive parts in the fractal vice. The challenge here was making this intricate part effectively distribute the clamping load force and not deform.

As with most of the parts of Fractal Vise, it's machined to a very specific clearance to enable a smooth motion so it can easily wrap around funky shapes, but also to keep the jaws perpendicular to one another. This is very important in a multi-stage vice, as a build up of tolerances can cause all kinds of clamping issues.

The Small Fractal

The business jaws, machined from martensitic stainless steel that's then put through a hardening process which changes the crystalline structure of the metal to make it super hard all the way though, not just a surface treatment like you see on most metals.

This gives these small delicate parts a disproportional strength, so they don’t bend or deform. Metallurgy at its finest.

The Upper Fixed Jaw

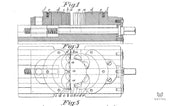

The backbone of the vice and the second most expensive part. This is another difficult part to make with an internal groove on which the fractal slides, and is much like the original patent. Each vice has two of these fun parts keeping them nice and symmetrical, so the jaws can be interchanged or reversed. It forms part of our upgrades from the original patent.

The Stub Shaft

Also known as a lead screw or power screw, this is the main part that controls all the nice vice-y movements. The fine thread allows for the precise adjustment and clamping action of the jaws. We have tested this extensively in some pretty grimy environments, so the thread can't bind up and will stay running smoothly. Just keep it away from pizza; for some reason this causes a total shut down until pizza is consumed or removed from the mechanism 🥷🐢🍕.

The Ring Of Brass

Every stub shaft needs a brass ring, right? An essential piece that most vices don’t have. This acts as a bearing surface, so when you're winding the jaws together it keeps that motion silky smooth every time. Unnecessary maybe, but it feels damn good.

We did want a shot of the ring by itself, but once they're press fit onto the stub, they're there to stay!

The Posts Of Power

These unassuming metal posts were specially engineered to behave like a miniature shoulder screw. These hold in the fractal jaws and align them into the slide grooves, allowing them to move smoothly when pressure is applied to the jaws. We wanted to make these easy to access and undo, so changing between jaws and general maintenance would be much easier to do.

The design of these pins is one of the big differences from the original patent and wouldn't have been possible to make and implement in 1913. How the times change!

The Silicone Base

A removable inert silicone pad that adds a surprising amount of grip. We spent a long time debating and testing various silicones until we landed upon this one. This is a nice thick part so it won't crack or split, and as with everything we do it can be easily removed for maintenance and cleaning.

The Cross Bar

The cross bar, or “tommy bar” to the initiated, is deliberately removable, so you can adjust the vice with or without it. This gives you some extra clamping power or a speedy winding in or out. Alternately you can take it out for some fine adjustment or if it's just getting in the way!

Don’t let his size deceive you- this little bar can handle some serious load!

The Cross Bar Cap

Of course, what cross bar would be complete without a cap, and hats off to this one. Made from brass so it won’t damage anything it knocks into, one on each end will screw into the Cross Bar making it easy to remove.

The Lower Sliding Jaw

A simple but vital part of the whole vice. This is the part that slides on the guide rails and has the connecting thread to the stub shaft. It’s safe to say things would be pretty static without this part. We also added multiple points where you can connect the jaws so that you can customise the opening distance when the jaws are reversed for internal diameter clamping. They also allowed us an attachment point for the parallel jaws and any future clamping doodads we all come up with.

Not bad for what looks like a simple block, to the untrained eye.

The (Not So) Sliding Base

Connected directly to the underside of the sliding jaw, we have the sliding base! Probably somewhat incorrectly named, as it holds the silicone and other attaching points preventing the vice from sliding around… but never mind, maybe it will slide one day.

The Lower Fixed Jaw

The core of the Fractal Vise. The fixed lower jaw pins everything together, fixing the slide rails and the screw thread to a single point with the fractals attaching to the top. This finely machined block ended up with some very intricate features allowing all the parts to jigsaw into it perfectly, meaning it can be miniature but still lock everything together.

It's the equivalent of a Swiss Army Knife, with what seems like magic allowing this number of parts to fit into it! Is this MetMo Magic?

The Fixed Base Plate

This base plate is fixed! This originally was designed to be used as a connector plate to the vice next to it, hence the extra holes we have in some images of it. However, we found this didn’t work very well and allowed the vice to move too much, so instead we designed the Dual Vise Adaptor Plate that lets you do this much better.

Now, this base plate's primary function is to protect the fixing point of the screw thread so it can’t vibrate undone. Perhaps overkill, but we are good at that.

The Guiding Dowels

Much like any good guide, these keep the vice on track. The hardened pins are tough- real tough. The kind of tough that takes all the teeth off a saw in one stroke. These have a vital job in the vice as they keep the two halves totally parallel when closing around an object, so it’s vital these don’t flex. That’s why we chose these ground rods that are much larger than they need to be, and are actually the same diameter that much larger vices would use.

The 5mm Dog Point Grubs

Getting down to the under-appreciated area of fixings with... the loyal dog point. A recurring favourite in the MetMo world, this nifty fixing both holds the stub shaft in place and at the same time lets it spin. Such a good grub. *pat pat*

The M5 Basic Grubs

Next in line, the standard grub screw. Used throughout the Fractal Vise to hold the dowels in place and prevent grit from getting into any spare fixing points. They give a nice seamless finish, and in the case of the fixed lower jaw lets us stack fixings next to each other in a very tight space. He’s the real life of the party.

The M5 Security Cap Screw

We always try to use the best, and security screws are at the top of their game. High tensile steel with a load capacity of 12.4 kN and a shear load of 10.2 kN, these guys are not messing around. With two of these installed in each set of fractals, you would have to put 2080kg (4585 pounds) of force through the vice to break one side.

It’s safe to say these things could probably be used to hold back the incursion of Cthulhu.

The M4 Low Profile Cap Screw

The smallest of the cap head family, these little fellas sit neatly inside the (not so) sliding base, letting the design sit in a smaller form factor and still provide a solid strength fixing for attaching the vice to the ball clamp and workstation.

Well that’s all, I hope you've enjoyed this week’s ramble into the details and hopefully it's shed some light onto the individual parts and how much work goes into them.

As always, if you have any questions or thoughts, just let us know in the comments below.

Share:

The one-way wriggle around worm gears

The hole history of manual drills