This week we’ll be getting our grubby little fractals around the testing data, delving into some FE analysis and finding out what it would actually take to break a (so far) indestructible Fractal Vise. We’ll also cover some real-world load testing, ad’vise’ around screw torques and explore the development story of our little Fractal Vise.

Before we jump right into the now, let us first travel back in time, to a land where metal fractals we're merely a YouTube spectacle, shrouded in their rarity and lauded over as an engineering masterpiece...

The Origin Story

Before Fractal Vise our shelves were littered with clampy contraptions, from rotatory pin vices to worm driven fractal claws. Early on our aim was simple; if it clamps, it gets printed.

Looking back through the archives of 2023-2024 it’s clear we had a lot of fun playing around with some very interesting mechanisms, so we thought this would be the perfect time to take you on a journey through our clamps and find out how we developed Fractal Vise and where it all began.

As with all MetMo contraptions, the story begins on Sean's desk. A place of almost realised dreams, littered with half-baked prototypes and an open but untouched bag of truffle flavoured crisps (is truffle actually good? Am I missing something?).

As time went on the brief was fully formed and we set out to design the perfect clamp to hold small models, 3D prints, and intricate components that would work with Multi Drive and expand on the desktop workshop concept. This allowed us to explore some really fun mechanisms, and this first concept is still one of my favourites...

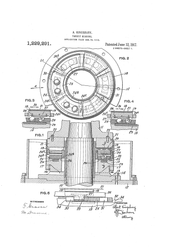

The Rotary Pin Vice

If you were to look at this vice, you’d be hard pressed to think it was anything other than a standard jewellers vice, with its trademark array of pins for holding… you guessed it… jewellery! Now, these vices are super useful and have also been adopted by the model making community to help hold funky shapes whilst working on them.

This vice really starts to come alive when you twist its undercarriage, (not too hard though, otherwise he pops off his track prematurely and we all know that's not ideal) using an array of bevel gears and clockwise/anti-clockwise drive shafts, we turned a simple twisting motion into the linear motion you can see in the jaws below.

This concept was a lot of fun to build and play with, but the ergonomics of using it in the real world really let it down. We wanted a highly mobile vice you could easily move around your workspace, and this vice required the base to be fixed, otherwise you needed three hands to hold your workpiece, rotate the adjuster, and stop the entire vice from spinning around. Not ideal really, so on the shelf it went and back to the drawing board we go.

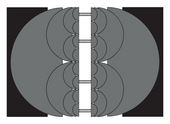

The Fractals of Life

This next concept was where we really started playing around with fractals and as you can see, the fractals themselves remain almost unchanged from this concept to the final Fractal Vise. There were many fractal ideas at this point and some of which we’re actually exploring further, so best not show those too soon 😜

Loosely based on the ‘Jaws of life’ that are used to tear off car doors, our much safer design uses a worm gear arrangement, and similar to our rotary vice this gear setup allows the transmission of a rotary motion around one axis to be translated to another axis entirely.

Worm gears deserve a blog post all on their own, but in the interest of efficiency let's summarise: A worm gear is a gear arrangement where a screw-like worm meshes with a helical gear (worm wheel) to achieve high torque reduction and non-reversible motion in a compact setup.

In other words, turning the thumb screw at the back of this design generates a serious amount of torque on those clamping arms resulting in a very high clamping force. Even in plastic, this design causes serious finger pain if you go one turn too far.

We tried quite a few different gear ratios, arm lengths and clamping heads and eventually concluded that this design… is pretty awesome 😜 but it didn’t really hit the brief we set out to fulfil, so it now waits patiently on the shelf awaiting its time in the spotlight… maybe.

The MetMo Cube… Vice!

This is where we started to explore more traditional vice ideas and this idea actually made it to a full metal prototype, but more on that later.

With this design you can start to see the beginnings of the Fractal Vise lower mechanism, and this concept helped us appreciate how important perpendicularity is in vice design. This refers to the rigidity of the two jaws as any slack in the lower mechanism is amplified as you move further up the jaw surface, and this usually results in a V shape as the jaws come together. As you can imagine, trying to clamp something with a V shape will just slowly extrude your part upwards and out of the clamping area… not ideal, and not a good clamp.

This is why we pay such close attention to the precision ground dowels and corresponding holes in the Fractal Vise, as any relaxing of those tolerances can have some pretty negative effects (and not to mention the vice starts to feel a bit budget if everything rattles around).

Delving deeper into the world of cubes we began experimenting with different sizes, varying weights and even started to explore the use of silicone rubber as a foot material. This is where the vice started to get really useful.

We tested these vices quite extensively and found the flat uniform sides especially useful to easily move and rotate your clamped workpieces around your desk. This was a big tick in the ‘YES’ column for our final design and is a feature we kept for Fractal Vise, along with a lot of the basic mechanics too, as this very simple design was very close to fulfilling our initial brief.

Introducing the MetMo Cube Vise

The final form of the Cube Vise concept and if I don’t say so myself, it looks pretty incredible.

With its solid stainless construction and a full panel of brass on the clamping surfaces, this design was so close to becoming a new MetMo and if it wasn’t for us being so obsessed with fractals, this would be a very different campaign!

During testing of this design, it became apparent pretty early on that this was a good vice. But ‘good’ isn’t what we’re about.

It clamped things well enough and behaved like a good old standard vice. But when it came to clamping our prints and models, it really wasn’t up to the challenge and much like we’ve shown in the campaign, the two pinch points let irregular or round shapes just spin around or not be clamped at all.

However, for flat shapes this vise rules supreme and is what inspired out Flat Soft Jaws in the Fractal Vise add-ons.

A Collision Of Ideas

What happens when an immovable cube meets a frog shaped recursion?

You can see where we’re going with this. You take the fractals from our ‘Jaws of life’ and the rigid structure we developed during the era of the Cube, sprinkle on some optimisation dust and a healthy dose of MetMo magic and you get the beginnings of the Fractal Vise!

After a few iterations we quickly landed on the correct form, then delved into the more technical aspects including working on connection points and making sure everything was strong enough to withstand the hard life of a vice.

As with all of our projects on Kickstarter development doesn’t stop when we hit launch, and Fractal Vise is no different. During the campaign we’ve improved features, tweaked materials, and tested new designs entirely. Most of this was all down to you guys and one special mention we’d like to give is to @Scott Allen for pushing us to try some more specialised thread styles for the lead screw with his excellent ad'vise', which we are now prototyping. If all goes to plan you’ll be able to apply even more clamping pressure to your workpieces, which will help with very heavy duty use cases like using Fractal Vise in manual or CNC machines.

FE Analysis Is Elementally Fun

As promised we have the expanded delve into the inner workings of our FE analysis, looking at the some of the other testing and how we identified possible weak areas in the design.

But first for those of you who have no idea what I am talking about, don’t stress! FE, or finite element analysis, is a computer modelling method that basically uses some really smart maths to simulate very accurately how forces (not just limited to weight) will effect a part.

They use the same thing in simulating air for aviation, heat in rocket boosters, and even concrete in buildings. All done with the same aim, to visualise and solve weak points before coming to building your plane, rocket, or skyscraper. Or in our case, your Fractal Vise.

So, now you're all now FE experts following on from that, let's move on to our testing!

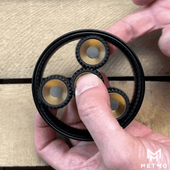

This simulation put 3000Nm on a single fractal, with the aim of identifying the weakest points of the smallest, and in theory most vulnerable, part of the design.

The deflection here is an exaggerated motion of how the metal moves so you can see it easier (the beauty of simulation); in real life this movement is only 18 microns- that’s the same thickness of a rubbish bag!

We also run the fixings through their paces in these simulations, directly comparing aluminium and stainless steel constructions.

Here we really ramped it up, pushing it all the way to 6000Nm with the aim of finding its breaking point which is something we would struggle to do in real life.

In this situation of a destruction level force being applied, that I could only assume would be like having an elephant come in and jump on one of the fractals, the stainless steel performed better than the aluminium as would be expected.

Aluminium moved by 160 microns (0.16 millimetres), whereas stainless steel moved by just 33 microns (which is 0.033mm)

Here we can see that in an exaggerated view to make it easier to see the movement. Considering the large forces here, they both performed well and fit our methodology of over engineering these things to withstand above and beyond what is needed. So next time you find an elephant at your workbench, you can rest assured your vice will survive… it’s these thoughts that keep me up at night.

Load Tests

Next up we have some specific testing that was done to see how much force can be exerted on the parts in the real world by a human. These are much less scientific and are more about getting an understanding of what a regular sized human hand can put on the vice, and by doing so, ensuring we are below the max tested loads of the static tests we did.

For stainless steel and aluminium here are the results!

Using the thumb screw to apply pressure

By comparison to the simulation, we were well under the max breaking points of any parts. Great success! We also discovered once again (like in most of our tests) the limits of the human hand... ouch.

Torquin About Torque

This one was requested a few times by you guys, and it's the recommended torque ratings of the various screws and fixing pins that go into the Fractal Vise.

1. T25 screws - 6nm Max

2. Fractal Pins – 0.2 nm Max

3. Grub screws – Flush with sliding base

4. Dowel Pin grub screws (internal) – 3nm Max (these fix the dowels in place)

5. Lead screw grub screw – Screw down fully then undo half a turn to allow the lead screw to spin freely.

6. Base Plate screws – 3nm Max

We've designed Fractal Vise to work if these aren't adhered to exactly, as most people don't have the necessary equipment to set these up perfectly.

As a bit more guidance, the T25 screws can take a lot of torque but only require a slight nipping up with an Allen key to function correctly (short end of the Allen key in the drive and push on the long arm until a firm resistance is felt).

Parts like the Fractal Pins don't need much tightening at all and over tightening them may damage the drive. They are simply preventing the fractals from falling off and are under no load once the fractals are in operation.

The only other screws worth expanding on are the grub screws that hold the dowel pins in place. These only need a slight tightening with the supplied Allen key and you will feel them clamp down on the dowel pins, locking them in place. Tightening this screw further will not improve the fit as it is merely stopping the pin from sliding out :)

Well that really got out of hand! If you've stuck with us till the end here well done, you've earned yourself a beer 🍺

Hopefully you've found this interesting and useful and it's filled in some of the gaps in the campaign that we couldn't fit in.

Share:

Time to torque about gearboxes

Planetary gears explained: A design written in the stars