Ask any maker their favourite tool and you’ll hear things like “my screwdriver because it causes mass destruction” or “my hammer because it can fix everything” or even “my 3D printer because it can make a flexi-rex”. But you’ll rarely hear someone mention their vise.

Granted, it might not be the flashiest tool in your workspace, but the noble vise is the unsung hero of many projects.

Some are quite literally grips above the rest. In fact, there are countless types and variations of those types. So the question on everyone’s lips: what makes one better than the next? And which one should you pick?

Before you run out the door to buy your next one, let’s tighten down on our decision making and explore the vises at our disposal.

Hold it right there. What is a vise?

A third hand would be lovely – imagine all the extra tinkering you could do. Unfortunately, the one my 3D printer has made isn’t much use. So I’m like you, and I’ve had to settle for a vise on my workbench.

A vise’s job is simple and often overlooked. It has to hold our workpiece firmly in place so we can sculpt, file, drill, saw, poke, sniff and whatever else we do with it – without losing a finger or eye. And do so accurately.

Some friendly vise advice

I don’t have to tell you not to chew sawdust. That’s common sense. So is using a vise. But there are mechanical menaces amongst us who like to push the limits of what a vise can (and will) do. I’m not saying you shouldn’t experiment; some projects need tool ‘adaptations’, sure. But there are some basic ground rules to follow. So, I’m going to fetch that dusty old manual in the corner of the room and share these rules with you.

Choose clamp-fully

Don’t use a pipe vise for a woodworking project. And vice versa. Match the vise to the material and task at hand. I know excuses to buy more tools are hard to come by, but if you’re working with multiple materials, you might need more than one vise. Sorry…

Lock in

A vise that wobbles isn’t a vise. It’s a finger-nipping fidget spinner. And the fun soon wears off, trust me. So, mount it like you mean it. Bolt that thing down and reinforce the area. Your projects (and fingers) will thank you for it.

Grit happens

J-j-j-j-uddery vises are just a pain. They’re easy to get on with but an unnecessary risk because if the jitters get bad enough, you might accidentally over-tighten and damage your workpiece. Keep your jaws squeaky clean and screw mechanisms and well-oiled.

When a good vise goes bad

They don’t get snappy and passive-aggressive. So you’ll have to manually check your vise for cracks, stress fractures and signs of fatigue. If you spot some damage, it’s time to tinker.

Handle with care. Not wrath.

I love the projects I work on too. But holding them within an inch of their life is not the right approach. This isn’t clampageddon. Firm pressure is fine. Too much grip can damage your vise and workpiece.

Align it (or forever hold your piece)

Make sure your workpieces sit flat and evenly inside your jaws – and then put them in your vise… [*looks around nervously*]. Misalignment means things wobble, and pressure concentrates in areas that don’t deserve it. Again, this can damage, warp or break your workpiece.

Keep your eyes

Protect your eyes. And your face. Wear safety goggles or glasses, and use a shield if you’re grinding or cutting. While your vise shouldn’t move, that doesn’t mean your tools or shrapnel won't.

Type of vises

Okay, enough of the common sense. Let’s explore some of the types of vises.

The Sawdust-Squeezing Wood Vise

These are often built into (or mounted to) the bench, and they’re great for gripping softer materials without inflicting any damage. Materials like, I don’t know, wood, maybe? They usually have wide wooden or plastic jaws so they don’t mark your workpiece, quick-release screw designs (for faster clamping/releasing), and then two guide rods to keep the jaws parallel as they move.

But ‘wood vise’ is a bit vague, especially when there are so many variations.

For example, you have front vises (that mount on the front edge of the bench). Then there are face, shoulder and leg front vises too. You’d use these to hold pieces vertically to make your planing or chiselling more comfortable. You also have end vises (e.g. tail vise or wagon vise). These mount to the end of the bench and are used with bench dogs to hold long pieces. You can look at these wood vises in more detail here.

The No-Nonsense Machinist Vise

Machinist vise. Engineer vise. Toma(y)to. Tomato. The term is used interchangeably, but they mean the same thing, and they're both where precision and punishment collide.

They typically have a cast iron or steel construction and use harder and stronger jaws compared to wood vises because they have to hold heavier pieces. Machinist vises also boast more precise alignment.

If you need to, you can replace or cover the jaws with a softer material to better protect whatever they’re cuddling. Often, they also have a swivel base (for better accessibility) and a built-in anvil section so you can hammer to your heart’s content. Alongside pulverising bits of metal, you can use a machinist vise for drilling, filing, cutting and tapping too.

As with lots of tools, folks like us tend to prefer older ones because they’re generally built better.

The Tiny (but Mighty) Watchmaker’s and Jeweller’s Vise

On the flip side, you have the watchmaker’s and jeweller’s vise. This is designed for more intricate work like crafting, repairing, soldering or engraving rings, pendants, watches or electronics. It’d also be the ideal vise to paint your model chicken’s claws.

They can feature soft padded jaws (usually leather or rubber inserts) to protect those fragile slithers of silver. So they also don’t exert massive amounts of pressure – enough to hold but not enough to crush.

Because they work such fiddly pieces – and everything seems to be so fiddly these days – there are a few types:

● Bench vises that fix to the bench

● Hand vises that are portable

● Ball vises that allow multi-directional movement

Similarly, their jaw width is comparatively lower (~50mm depending on the vise). You don’t want your vise (or floor) gobbling up a precious ring, now do you?

The Tube-Taming Pipe Vise

If you hadn’t noticed, the vises so far hold mostly straight workpieces. You know, nice, level jaws and nice, smooth, straight stuff. So what about the round workpieces? They need holding too.

When your work is more tube than cube, a pipe vise is your new assistant. It grips round pipes, tubes and other round surfaces securely. As you’d expect, these jaws don’t look like your typical ones. See:

These are important tools in the plumbing and pipe-work world and make modifying pipes/round stuff far easier (e.g. threading, cutting or welding). There are a few types: yoke-style (top clamp and v-shaped base), chain-style (the chain wraps around the pipe and tightens) and hinged (fold-open clam style with a hinged top jaw).

They’re portable and typically used on job sites or fitted to mobile rigs. Some benchtop vises have pipe jaws integrated into them, too.

The Space-Saving Clamp-On (or Suction) Vise

For the hobbyists among us, your makerspace might have limited elbow room. Having both a vise and work surface space can be a lot to ask for. So a clamp-on or suction vise can be a great asset to your toolbox.

They’re not known for their clamping power, but they are known for their versatility. They attach to your workbench/tabletop quickly, and because they’re usually a little smaller, you can tuck them away when you’re finished. They’re often made from aluminium or plastic and are great for pop-up hobby tasks.

The Swiss-Army (Combination) Vise

These are a bit like a 'jack of all trades'. They have interchangeable jaws for flat, round or irregular shapes. They can rotate, have built-in-anvils, and even pipe-holding grooves. But it comes at the cost of accuracy.

If you're one of the space-limited folks or casual evening tinkerers, a combination vise is very handy because you need fewer tools and less space to get the job done. But for the more specialist and demanding applications, then a specific vise will be a better choice.

The Heavy-Duty Blacksmith’s Leg Vise

The blacksmith’s leg vise is anchored to the floor and flexes its impressive holding strength. They are designed for… err… blacksmithing. So they can withstand a heavy hammering at high temperatures.

One leg extends to the ground, allowing the vise to transfer load downwards – rather than across the worktop. They have large jaw openings and might be considered the Chuck Norris of the vise world: rugged.

The ‘My Whittle Helper’ Carver’s Vise

I think this might be the most ‘out there’ vise so far. The carver’s vise is a specialised tool designed to hold irregularly shaped workpieces like wooden sculptures. It prioritises flexibility and accessibility to the piece. So, it has:

● 360-degree rotation, meaning rotation on multiple axes so you don’t have to reposition the piece manually

● Tilt-functionality, so you can tilt the piece and get your hands exactly where you want

● Multiple mounting options (e.g. it can bolt directly to your workbench or be used with dog holes for portability)

Typically, you’d mount this to your bench (either clamp or bolt) and attach your workpiece, which can be screwed onto (either via a mounting block, faceplate - like a lathe - or directly) the top section that moves about. You aren’t going to be hammering into this because its clamping forces are much, much lower. But it's more than apt for a casual carving or whittling session.

Here’s a video showing one of these in action.

The Back-Saving Moxon vise

The moxon vise is a special piece. It’s used to elevate (not in the cringey, tech-bro way) but literally. It raises the workpiece to a comfortable height using a twin-screw design. They’re often used for dovetailing, tenoning, edge jointing, and even clamping tapered pieces. Save your back and neck. Get a moxon vise.

When workpieces don’t play ball

But what if your parts don’t play by the rules? What if you need to clamp a really odd piece – like your pet dragon or banana? What if your piece is smothered in irregular geometries?

Yes, you have the carver vise. But what if you want to hold stones or something that can’t be mounted? What if you just want a vise that can do it all – and look damn cool at the same time?

You see, a normal vise is nice. But this one is genius…

The Shape-Shifting Fractal vise

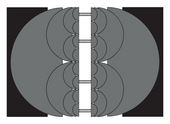

This wondrous bit of kit that can hold, caress and nurture a workpiece of any shape is known as a fractal vise. It uses a series of pivoting, nested jaws that adjust independently to fit the shape of the clamped object. You might want to skin a pear with a scalpel, rub a tightly held stone, or get up close and personal with your recent 3D-printed creation. Its shape doesn't matter. The fractal vise will hold it with ease. And because the jaws pivot, it distributes force evenly too!

They are an early 1900s creation, and after HandToolRescue’s YouTube video went viral, there was a surge in demand – with no supply.

Folks started 3D printing them and looking for expensive modifiable alternatives. And like the curiously-minded engineers and machinists we are, we thought: “We could make that!”

The MetMo Fractal vise

From a 100-year-old concept to an internet sensation to a modern engineering revival. This is a tool with history, mystery and a serious grip on the future. The MetMo fractal vise is made for the maker who tackles the unpredictable... which, let's be honest, is all of us.

Despite its intricate design, the vise is still surprisingly compact, endlessly versatile and bench-ready straight out of the box. It comes with some fractical extras:

● Long jaws for more surface contact

● Soft jaws for delicate parts

● Straight jaws for the classic, conventional clamping

● And a long-travel version for bigger, bulkier workpieces

Underneath, you’ll spot fixing points. So you can bolt it down to your workbench or even fit it inside your current vise. Heck, the MetMo fractal vise is even small enough to fit inside your pocket!

But the coolest feature of all is that the vise is reversible. In other words, you can clamp on the inside diameter of any object, too! It really is the most fractical vise ever.

If you’re interested, you can learn more about it on our Kickstarter page here.

Clamp it up and call it a day

Lots of vises for lots of workpieces and spaces. Some do more than others. But some do jobs better than others. Now you know some of what’s out there, when to use each one, and have another reason to boost your tool collection.

If you’ve got some cool (or embarrassing) tool stories, share them with us in our CubeClub and/or Reddit. We’re always happy to laugh with (or at) you. Lol. See you next time!

Share:

An Ultimate Case

Getting Down And Knurley