The MetMo Blog

We love all things engineering. From deep dives into our products to historical explorations, there’s a wealth of information just waiting for you on the MetMo blog!

Pro tip! Search ‘Pocket Driver’ to get your descent into MetMo started.

Latest Blog Posts

A seamless look into Wire Electrical Discharge Machining (Wire EDM)

Pocket Driver: Pre-Production Run

In our latest blog post, we take you behind the scenes of the Pocket Driver's pre-production run. While we were thrilled to see our design come to life, we also encountered some challenges that pushed us to refine our tool even further.

Pocket Driver: Origins, Development & Production

We've been busy crafting the MetMo Pocket Driver—a compact tool that blends classic design with modern engineering. Inspired by a 1920s ratchet screwdriver, we’ve miniaturised it to fit comfortably in your pocket without compromising on performance.

The journey began with prototyping, refining the tool's design for optimal functionality. Once the prototype was perfected, we moved to production. The handle is machined from a solid billet of 2024 aluminium using a 5-axis CNC milling machine, ensuring precision and durability. Each part undergoes meticulous quality control to meet our high standards.

In our latest blog post, Driving Deep into the Details, we take you behind the scenes of the MetMo Driver's design and manufacturing process. From the precision-machined chuck and barrel to the custom brass bush and hardened barrel pin, we delve into the engineering choices that make our driver stand out.

We also discuss the evolution of the barrel design, including the use of aerospace-grade 7055 T77 aluminium for strength and durability.

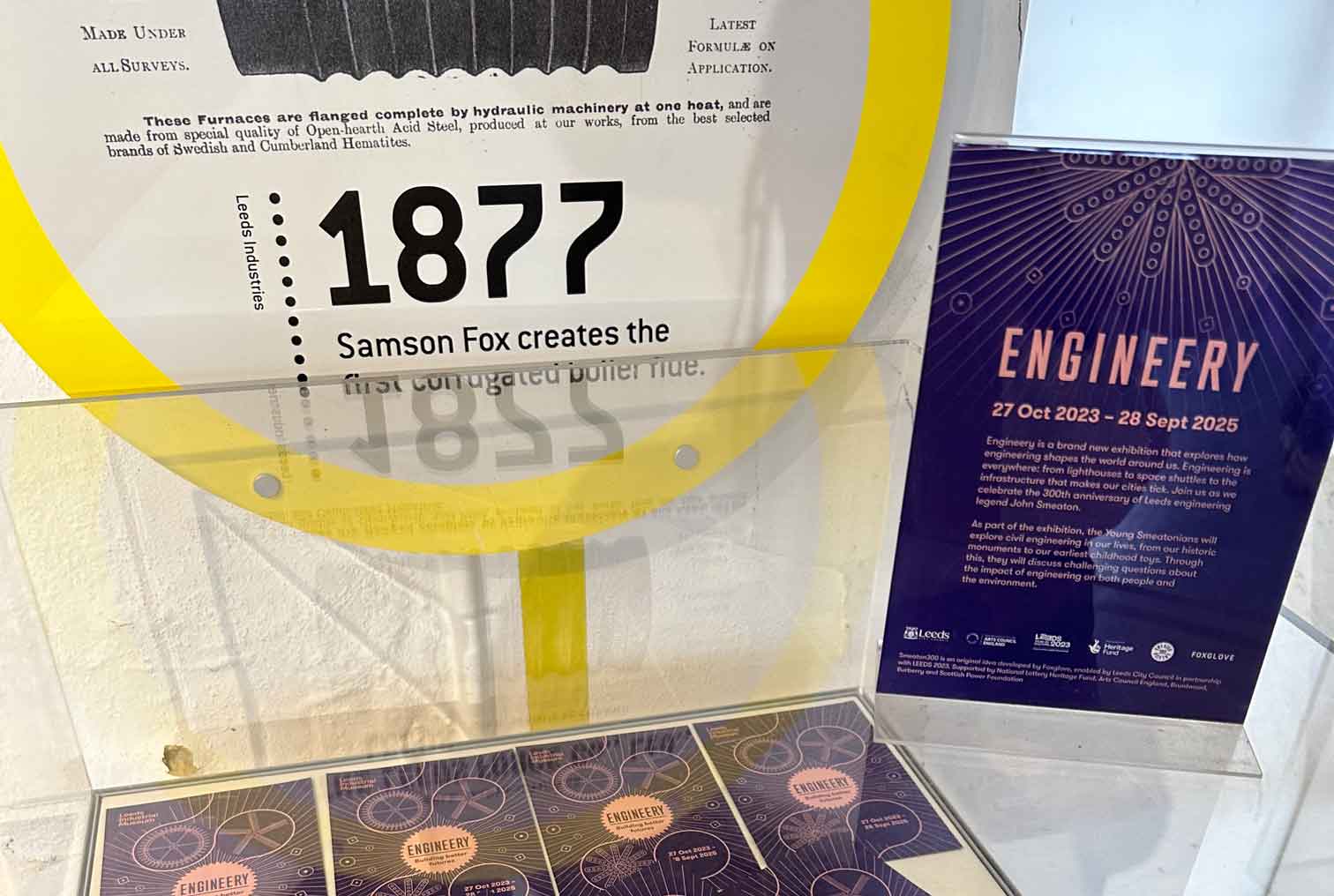

In our latest blog post, we share our visit to the Leeds Industrial Museum during the "Engineery" exhibit, celebrating the 300th anniversary of John Smeaton, the "Father of Civil Engineering." The museum, housed in a 16th-century wool mill, showcases a rich history of textile manufacturing and industrial innovation.

Ever wondered how your MetMo Pocket Driver goes from a solid billet of aluminium to the sleek tool in your hand? In this post, we take you behind the scenes of our CNC machining process.

n our latest blog post, A Case for Your Bits, we introduce the Magnetic Bit Case—a sleek, multifunctional accessory designed to complement the MetMo Pocket Driver. Crafted from lightweight aerospace-grade aluminium, this compact case features a pop-out handle and a powerful neodymium magnet, offering a satisfying and efficient way to store and access your bits.

At MetMo, we believe in blending precision with practicality. In our latest blog post, How to Make a Pocket, we delve into the meticulous process of crafting the MetMo Pocket Driver—a tool that embodies our commitment to quality and innovation.

In our latest blog post, Driving Deep into the Details, we take you behind the scenes of the MetMo Driver's design and manufacturing process. From the precision-machined chuck and barrel to the custom brass bush and hardened barrel pin, we delve into the engineering choices that make our driver stand out.

We also discuss the evolution of the barrel design, including the use of aerospace-grade 7055 T77 aluminium for strength and durability.