The MetMo Blog

We love all things engineering. From deep dives into our products to historical explorations, there’s a wealth of information just waiting for you on the MetMo blog!

Pro tip! Search ‘Pocket Driver’ to get your descent into MetMo started.

Latest Blog Posts

Take A Look At Our Little Bits

The Fractal Vise is made up of 17 unique parts and 46 components, each designed with precision and purpose. From the Medium Fractal at the core to the hardened Small Fractals and symmetrical Upper Fixed Jaws, every element plays a role in delivering smooth, reliable clamping. The Stub Shaft controls movement, aided by a brass ring for silky turns, while the Posts of Power and guiding dowels keep everything aligned and running true. Even the silicone base and cross bar are carefully considered for grip and adjustability.

Behind the scenes, a mix of hardened steels, over-engineered fasteners, and thoughtful upgrades ensure strength, durability, and a satisfyingly refined experience. It’s compact, clever, and overbuilt in all the right ways—because why settle for less?

Discover the art of knurling in MetMo's latest blog post, Getting Down and Knurley. Learn how this precision engineering technique enhances tool grip, functionality, and aesthetic appeal. Explore different knurl patterns, suitable materials, and the machinery behind the process. At MetMo, we blend craftsmanship with innovation to create tools that stand out in both design and performance.

Helical gears are the best thing since sliced thread

But helical gears are great – to look at and to use. And you’ll find them in a lot of places. So let’s get our butts into gear and explore these smooth criminals of the engineering world.

Every great product starts somewhere—often in a workshop full of wild ideas, exploded prototypes, and the occasional insurance risk! In this behind-the-scenes dive, we look back at the curious contraptions and “what-were-we-thinking” builds that eventually led to the sleek, refined Multi Drive.

From the Danger Knife (aka a high-precision vacuum-launched foot-stabber), to a ratchet mechanism so tiny it needed dental-grade tools to make, to a PEEK plastic prototype that felt more like a sponge than a screwdriver—each misstep taught us something valuable (and occasionally hilarious).

And let’s not forget the 3kg brass One Tonne Case, which looked cool, felt like a Bond gadget, and required serious biceps to carry.

These discarded designs are more than just failures—they’re part of the MetMo DNA: over-engineered, beautifully mad, and a bit dangerous. Because building something great means getting your hands dirty and your desk a bit scorched.

We’re tearing apart the Multi Drive and looking at each piece in excruciating detail.

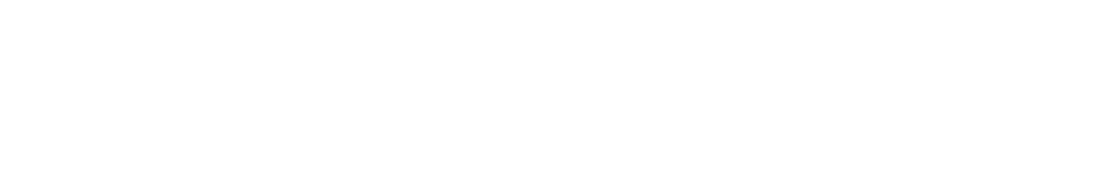

How aerodynamic bearings became engineering’s smoothest operators

We delve into the fascinating world of air bearings—components that use a thin film of pressurised gas to provide a low-friction interface between surfaces.

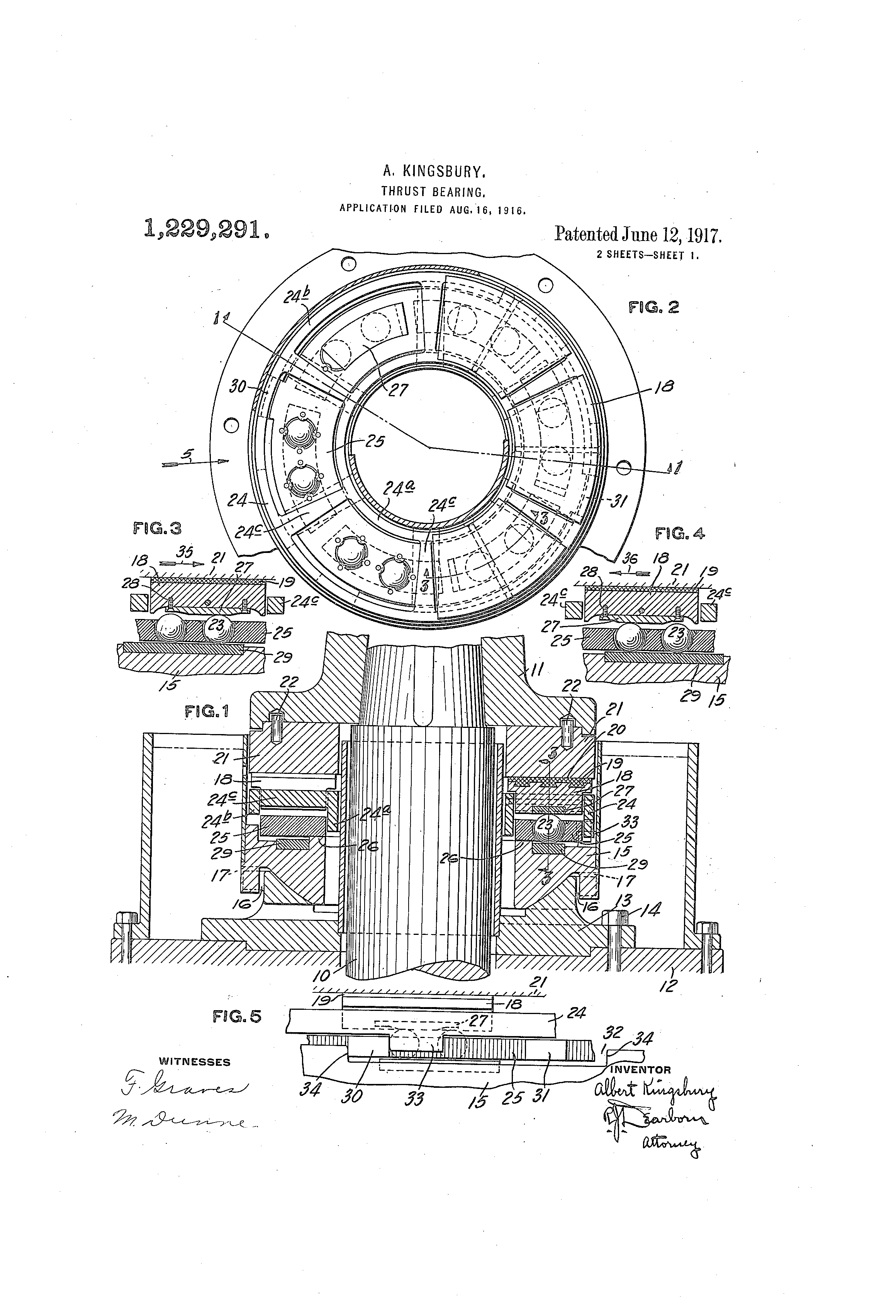

In our latest blog post, "Making a Multi Drive," we take you behind the scenes of crafting the MetMo Multi Drive prototype. Before finalizing the design, we created a working model from mild steel to test functionality and identify potential manufacturing issues. This hands-on approach allowed us to refine the tool's design and ensure it met our high standards.

Pocket Driver: From Silver to Gold

In our latest blog post, "Pocket Driver: From Silver to Gold," we share the journey of transforming our polished stainless steel Pocket Drivers into gleaming gold-plated masterpieces.