It has been a long journey since we first started to make our first product, the MetMo cube.

Made for designers, engineers, thinkers, and anyone who wants to just take a moment and focus, relieve stress, or simply play around.

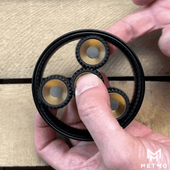

Simply invert the cube and let gravity get to work. The tolerances we've machined the cube to are so fine that we had to design a special base to allow the air to escape at a controlled rate. It's an oddly satisfying cube that works in the palm of your hand.

We love pushing the boundaries with machining techniques. The process we've used to create this is called wire EDM (electrical discharge machining) and it's now so advanced that in some industries cuts are being made to 0.02mm, with tolerances being held to +/- 0.001mm!

To put that into perspective, the average width of a human hair is only 0.08mm! That's how we achieve such a seamless and mesmerizing effect.

We now make these exclusively in the UK in very limited batches of 50 every 6 months as it takes this much time to finish a batch to a high enough standard that we are happy with.

Each one has a precision laser-sintered 3D printed base that tightly regulates the airflow through the cube to give it the most satisfying pneumatic motion.

The level of engineering that goes into creating something this precise is very specialist.

It takes a great deal of skill, time, and extremely expensive machinery to create the MetMo Cube. You might have seen some YouTube videos of similar objects, but they're only very costly demos. This is still the world's first metal motion cube you can actually own for these reasons!

Technical Data

Weight: 500 grams

Size: 40mm x 40mm (1.57in x 1.57in)

Finish: Brushed Finish

Machining Method: Wire EDM

The cube is made from solid stainless steel and weighs in at a reassuring 500 grams. It's super satisfying to hold, fiddle with or even just stare at. Each side has been ground completely flat, and then a brushed finish is applied so the surface is super smooth to touch.

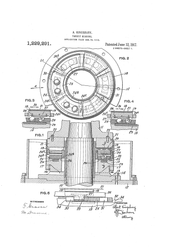

So, What Actually Is EDM?

Electrical Discharge Machining is a method of shaping metal to extreme tolerances and uses an extremely thin wire to cut through solid metals. If you'd like an in-depth rundown of the process and fancy learning how it works, we'd recommend checking out some YouTube videos for wire EDM.

Why is this special?

EDM allows us to make very, very precise shapes, structures and parts to perform very specific tasks where extreme tolerances are required. The interaction of the parts in our cube cannot be replicated using laser cutting, casting or CNC machining.

MetMo Cube gives you access and ownership to a very special form of engineering technology, usually reserved for high-budget engineering programs and cutting-edge research.

Why isn't everything made like this?

EDM remains a niche manufacturing method and is also very expensive. As such, most EDM made products are for specialist purposes, such as space exploration and aviation engineering. There are also limitations to what EDM can achieve and the reduced cost and flexibility of other metal cutting methods, such as CNC machining and laser cutting, puts EDM fairly low down the list of preferred manufacturing techniques.

Exclusively MetMo

Want to get Metal Motion for someone as a gift? It's perfect for any office, studio or workshop and really is one-of-a-kind. Each MetMo is expertly finished and comes with a unique personalized authenticity card with its very own serial number.

Check out the MetMo Cube in our shop and sign up to know when the next batch will be ready.

Share:

A Gripping Strip Down

The Next Generation of MetMo is Here