MetMo Stainless Steel Wrench Grip

- Adjustable stainless steel wrench

- Aerospace-grade full metal construction to last a lifetime

- Clamping force of 1.2kg means you can get the job done

An icon of industry re-imagined to get a grip on the 21st Century, a piece of engineering history re-imagined for the modern day. MetMo Grip is both a fidget toy and tool, keeping you satisfied for hours on end either fiddling with it or using it to clamp the life out of something.

Materials

Stainless Steel (316 grade)

Hard Anodised Aluminium (6061 aerospace grade aluminium)

Carbon Steel (1020 grade)

Shipping & Returns

Available to ship immediately.

30 day returns policy.

Dimensions

Size: 180mm x (7.0") x 60mm (2.36") x 13mm (0.5")

Weight: 300g (10.5 Oz)

Technical Details

Machining Method: CNC Machining

Jaw Aperture: 0 - 22.5mm (0 - 0.885")

What's in the box?

- MetMo Grip

MetMo Stainless Steel Wrench Grip

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

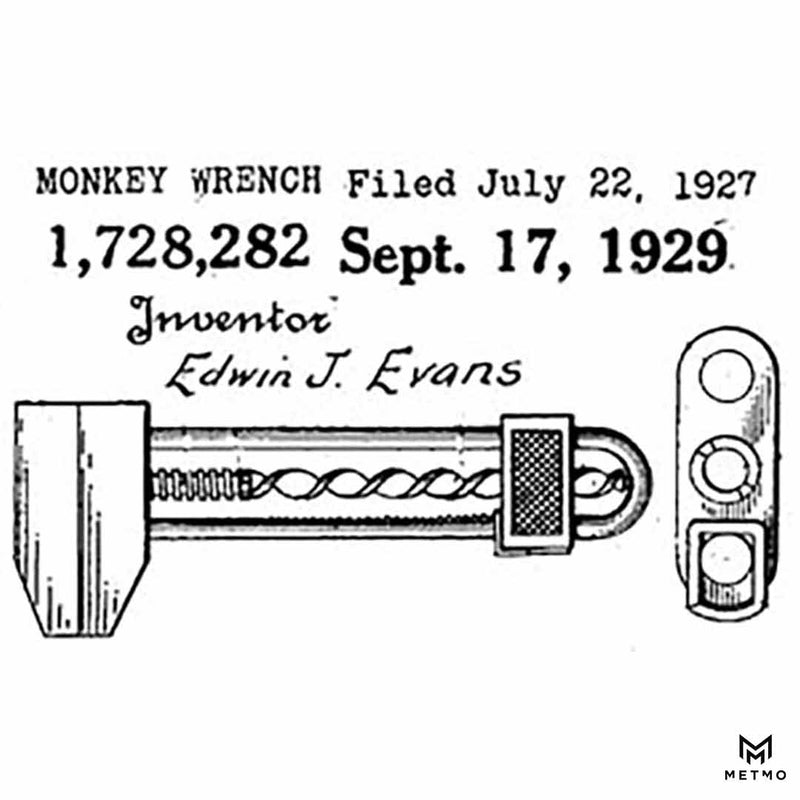

Getting to Grips...With History!

Nowadays, we're all used to seeing the adjustable wrenches that come in every multi-piece toolkit from Scandinavian stores or where-have-you.

Before the era of the modern adjustable wrench, there was a bloody conflict in the early part of the 20th Century. A conflict which today remains largely forgotten, but is of the utmost importance to the development of modern day tools.

We speak, of course, of the Wrench Wars.

The Wrench Wars

During the Wrench Wars, the battle for supremacy in the world of the adjustable wrench was fought by many companies, some of which remain in business to this day.

Unfortunately for many firms, they lost out and their designs fell by the wayside. One of those designs that never quite made it into the big leagues was the concept MetMo Grip was inspired by.

Why Have We Created MetMo Grip?

We found a patent of an early 20th Century variable grip wrench and immediately fell in love with the concept.

Monkeying Around With The Past

MetMo Grip is our tribute to the furious innovation at the start of the last century which lead to an overhaul in the means of production and design of everyday tools. Made using modern methods from contemporary materials, MetMo Grip is an engineering oddity and marvel that's as comfortable as a fidget toy as it is clamping together steel.

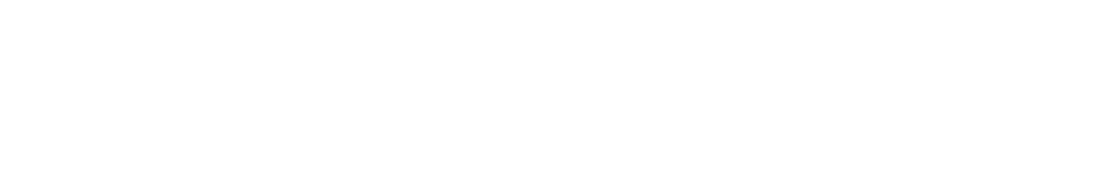

Gripping Features

We engineered in an array of useful features. From a standard 1/4 inch bit holder to a handy box opener, the MetMo Grip is ready to tackle your daily tasks with ease.

Who's it For?

Made for designers, engineers, thinkers, and anyone who wants to just take a moment to focus, relieve stress or just play around.

For the tool lover, or the biggest spanner you know, anyone can appreciate the might of the Grip.

A Fidget Toy That's Also a Handy Tool

The MetMo Grip isn't just a super satisfying desk toy, we made sure it could step up when a job needed doing, and do it well.

Satisfaction Zone

Simply sliding the jaws open and closed is huuuuuuugely satisfying. The weight feels reassuring in your hand, and you know that if you do ever need to get a grip on something MetMo is there for the job.

Snappy Gripping

No more fiddling with your adjustable wrenches, spinning the gear over and over until (maybe) you fix it in the right place. The MetMo Grip design is snappable in a second and securely locks in place so you get it right first time, every time.

Laser Focused

Laser engraved measurement markings on the Grip mean you can pre-set to a nut size. In a pinch you can whip out your Grip for a quick measurement, so you always have a handy size guide for your nuts.

Lefty, righty, metric, imperial - it doesn’t matter, because MetMo Grip does it all. Down the spine of the Grip, these measurement markings are easy to read.

No callipers? No problem! (...So long as you aren't working to +/-1mm).

Multi-Functional Back End

Not just an adjustable wrench, the Grip also has a driver bit holder, a box cutter, and a bottle opener built in to the jaws. A perfect workshop companion, your Grip can help with the task at hand.

What's MetMo Grip Made Of?

The Grip is machined from solid stainless steel, with a hard anodised 6061 aluminium adjuster.

316 stainless steel components form the body of MetMo Grip, with a precision formed solid rod and CNC machined jaws. The helix shaft is machined from 1020 passivated carbon steel that's ready to take on the rigours of any tough job.

6061 hard anodised aluminium is the chosen metal for the adjuster. Lightweight and durable, aluminium adds function without adding extra weight.

CNC Precision

Precision manufactured using five axis CNC machinery puts the Grip a cut above the rest. With the precise tolerances achievable with modern manufacturing, our re-imagining of this wrench is more fluid and satisfying than the original, as well as being stronger and more reliable.

Why This Design?

We found the original tool and immediately fell in love with just how satisfying it was to use and fiddle with. We found ourselves constantly playing with the mechanism whilst at our desks. It was so fascinating watching the motion and feeling the weight of such a well constructed tool, it left us feeling that this was something we just had to share with the world!

We set out to recreate this elderly design with a focus on making it useful as well as enjoyable, to have and to hold even when it's not being used as a tool.

Why Not a Modern Variable Wrench or Spanner?

We wanted the Grip to stand out against modern tools by keeping its vintage design roots, resembling the trusty engineers precision calipers.

We also wanted to honour the legacy and impact of the Wrench Wars. Without this period of rapid innovation, we'd likely have fewer options in terms of the tools we have today. Necessity begets invention, as they say, and though now a half-forgotten relic, the Grip style can make a comeback in the 21st Century.3

What's The Deal, Why Does It Cost £119.99?

The choice of materials in this product adds to the overall cost. As you probably know, stainless steel, while extremely durable, is costly and difficult to work with. Getting the threads of the Grip precision machined requires a specialist manufacturer, one who we've worked with before and who is capable of producing such critical components.

Normally tools are made from low cost metals that are stamped out, but not the Grip. We wanted to create a piece that was less mass manufactured and more fitting to the tool's heritage, as well as being top quality to last a lifetime.