A Journey To The Centre Of The Recursion

As a wise man once said, 'to move forward, we must first look back.' So that’s what we thought we'd kick off with, the history of this fascinating fractal mechanism.

Our story begins with Paulin Karl Kunze, of Vienna, Austria-Hungary. It looks like he was in engineering, either managing the shop floor of a production department or an engineering manager, it’s not totally clear.

An interesting side note: it's our second patent from that area of the world! It's not surprising since the area was known for tool manufacturing.

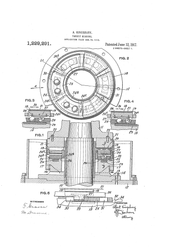

What we do know is that between February 1913 and October 1922 he registered his patent for a “Device for obtaining intimate contact with, engaging, or clamping bodies of any shape.” I’m sure that raised a few eyebrows. First registered in Austria, then the USA, the UK, and finally Switzerland in 1922.

From these original patents there is actually a lot going on, a lot more than just the vice. There's an adaptation for a fractal adjusting chair for instance, that I believe was reproduced more recently by Hand Tool Rescue. But also alongside that were the drawings for a press and metal handling roller for really big metal rods or tubes.

There was also a really exciting three dimensional fractal cradle to support large metal castings!

What was interesting with the 3D fractal is there would have been what can only be described as... fractal inception! With one set of jaws supporting another at 90 degrees and then on top of that a number of ball joints mounted on yet another set of ball joints. I can’t Imagine how this could be produced today, let alone back then by hand!

Interestingly, this intense fractal creation is cited in a number of patents since then but for use in various bearing supports, but I digress.

There's no real record of any of these original pieces ever existing; even the fractal vice designs in the patent are very different to what few exist today, as these early fractals were a number of half round shapes that were then essentially trapped between two plates of metal. This means the working area of them in practice would have been somewhat reduced from the later versions.

This brings us to the next phase of the vice, and where these things get gripping as they go into production.

In 1922 the patent was either sold or leased to a business in New York called Mantle & Co. (1907 Park Ave if you're local). These fine chaps look to have turned those patents into a usable vice and gave it a rebrand, proudly naming them the 'Mantle Vise' after one of the founders, Joseph G. C. Mantle.

This would have been the company that turned those patent ideas into a working product, swapping out the flat clamping of all the parts with neat, albeit much harder to machine, dovetail sliding joints that gives the vice its characteristic and recognisable look.

They also introduced the more 'machine vice' looking design, making two versions; one with a swivel base and one for direct to bench mounting.

It is these that are rare but still around to this day, a testament to their design and manufacture I like to think.

It sadly wasn’t a long lived product line, with most of the business getting sold to the United States Automatic Box Machinery Co. in Boston in 1928, where it was rebranded again as The BOSTON Universal—Self-aligning jaws of the Boston Universal Vise (catchy, right?). After that it was in a few publications but disappeared from any mention in history in 1929.

I really did try to find this business in Boston but there was no record of it or what happened to it after 1929, though it was around the era of the Great Depression so that could have been a contributing factor.

This era of engineering history is an interesting time. and until the early 30’s many products, machine tools, vices etc. were all made laboriously by hand. Things were changing fast with mass manufacturing techniques coming into in the mainstream, even for smaller factories.

"Why mention this?" I hear you ask! Well, any machinist will know you need a good datum or point of reference to start at when machining, and it takes a little bit of work to set up each time. So what some bright spark did a long time ago was to set up a workholding vice to allow a repeatable routine to be followed, machining part after part that was exactly the same as the last (or near enough back then) so you wouldn't have to spend your time setting up every time. Time is money after all, especially in a 1930’s production line.

That’s easy to do on a normal fixed vice because nothing moves around. On a fractal however it would be different every time, making it great for that difficult job that refuses to be clamped, but in a manufacturing environment where repeatability and production speed were becoming the norm the old mantle vice would have been seen as a bit unnecessary.

Not to say it wouldn’t have been a good vice for many still working on castings at the time, but like touch tone phones it would have been a shrinking market that eventually led to this vice falling into obscurity.

I should point out at some point here that the names back then were so descriptive because the word fractal didn’t exist (in this context) until the 1970’s where French mathematician, Benoit Mandelbrot did the maths and officially brought the concept and the word for us to use when describing this kind of vice, and I can only assume no one was getting stuck in recursions before then.

The maths in itself is quite fascinating and worth a look at, but I'll leave that for another day.

I hope you found my ramblings interesting and we all learned something about those original patents!

In other news, we've had a lot of requests for more details about the add-ons as well as testing of the different jaws, and high up on the list are a form of plastic jaws. We've heard you and we're working on all of these things! It will just take a couple of weeks to get it all together for you all.

Here's a peek at us playing around with a load cell in the fractal.