The MetMo Blog

We love all things engineering. From deep dives into our products to historical explorations, there’s a wealth of information just waiting for you on the MetMo blog!

Pro tip! Search ‘Driver History’ to really get your teeth in.

Latest Blog Posts

When it comes to engineering excellence, the tools you carry are only part of the story — how you carry them matters too. In An Ultimate Case, we take you behind the scenes of the design and development of the Multi Drive Expansion Kit: a storage solution as precisely crafted as the tool it protects. From material choices to the satisfying click of the magnetic closure, every detail was obsessively refined to balance durability, usability, and style. This isn't just a case — it's an experience built for creators who care as much about their gear as the projects they bring to life.

6 design principles that make any personal makerspace maketastic

Your makerspace is more than just a workbench—it's your creative command center. Whether you're soldering circuits, carving wood, or prototyping your next big idea, the design of your space can make or break your workflow. In this post, we dive into six essential design principles that turn any workspace into a maketastic haven of productivity, inspiration, and efficiency. From layout logic to storage hacks, these tips will help you build a space that works as hard as you do.

Say hello to The Stubster—your palm-sized, micro-handle sidekick that squeezes into tight spaces where the regular Multi Drive can’t reach. It packs all the same handy features as its full-size sibling—bit-holding, secure grip, quick-swapping—all wrapped into a compact powerhouse.

Helical gears are the best thing since sliced thread

But helical gears are great – to look at and to use. And you’ll find them in a lot of places. So let’s get our butts into gear and explore these smooth criminals of the engineering world.

Every great product starts somewhere—often in a workshop full of wild ideas, exploded prototypes, and the occasional insurance risk! In this behind-the-scenes dive, we look back at the curious contraptions and “what-were-we-thinking” builds that eventually led to the sleek, refined Multi Drive.

How to pick the right model-making tools (for a sanding ovation)

Why step up your tool game?

Your modelling skills will outgrow basic gear pretty fast. A sharp, sturdy setup lets you finesse details, save time, and spare your fingers the agony of crummy kits.

We’re tearing apart the Multi Drive and looking at each piece in excruciating detail.

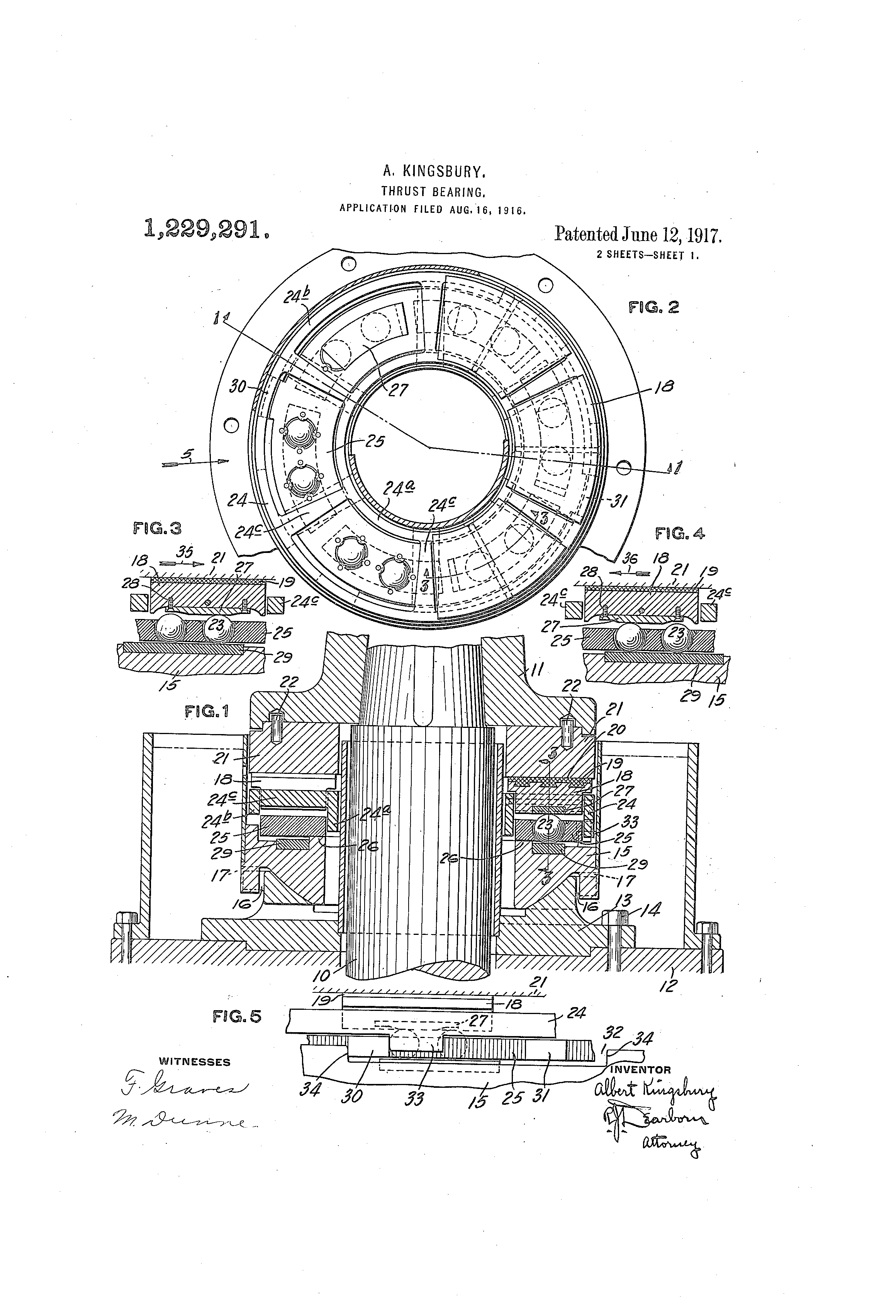

How aerodynamic bearings became engineering’s smoothest operators

We delve into the fascinating world of air bearings—components that use a thin film of pressurised gas to provide a low-friction interface between surfaces.

The ‘Watch-ima-collet’: The Time-Ticking History of The Collet

From dainty 18th‑century watch benches to roaring factory floors, the collet shows how micro‑innovations can power mega transformations. Tiny sleeve, massive impact—grip tight, friends!