Hey everyone!

We're now approaching the final stages of production so we just wanted to show you some behind the scenes images and footage of what's going on.

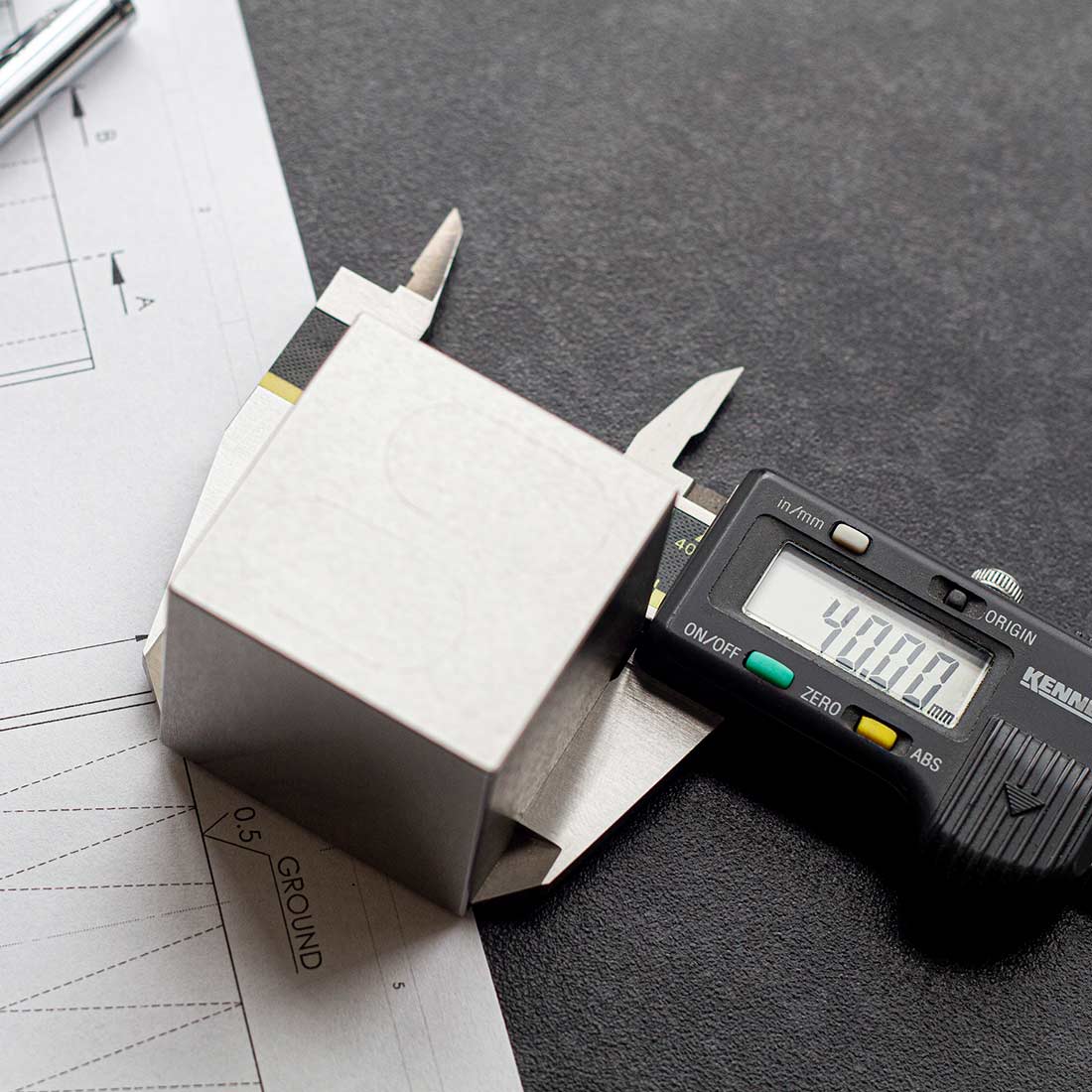

To get the best finish possible we use a process called precision grinding. This is done when the pins and cube are fully assembled, ensuring the components are completely flush with each other when you receive them. This helps to create the illusion of seamless metal in a finished MetMo.

At present we're around 75% complete in the manufacturing stage, with many of the cubes fully QC checked (this includes most of the GR2 titanium MetMos too).

In the mean time, all of the packaging is ready to go, shipping is all set up and we're still on schedule to begin posting at the end of November. This does rely on no logisitics hold-ups but fingers crossed it all goes smoothly.

Once they've arrived to us, we'll get on with packing and shipping right away so you can get your cubes as soon as possible.

Exciting times!

Team MetMo

Share:

Creating Cubes

Cubes on the Move